Six Sigma: Understand what it is and what it's for

Six Sigma is a set of practices aimed at systematically improving processes by eliminating defects. This methodology is quantitative, structured and disciplined, and aims at cost reduction, process optimization and customer satisfaction.

BMS Technology

In the Six Sigma concept, quality is an essential factor in any industrial segment. Added value to the customer is essential in the final delivery, be it a service, consultancy, project or product.

Inspired and in tune with the lean manufacturing, Six Sigma is another Lean methodology focused on extracting the maximum possible quality from companies.

What is Six Sigma?

Six Sigma is a set of practices aimed at systematically improving processes by eliminating defects. This methodology is quantitative, structured and disciplined, and aims at cost reduction, process optimization and customer satisfaction.

Any type of business can apply Six Sigma. This is because their practices are not limited to complex work and cover a wide range of possibilities. Thus helping to reduce the Lead Time of the processes.

The methodology is based on setting goals and creating strategies to achieve them. For this, data is collected and analyzed, implementing continuous improvements and seeking constant improvement.

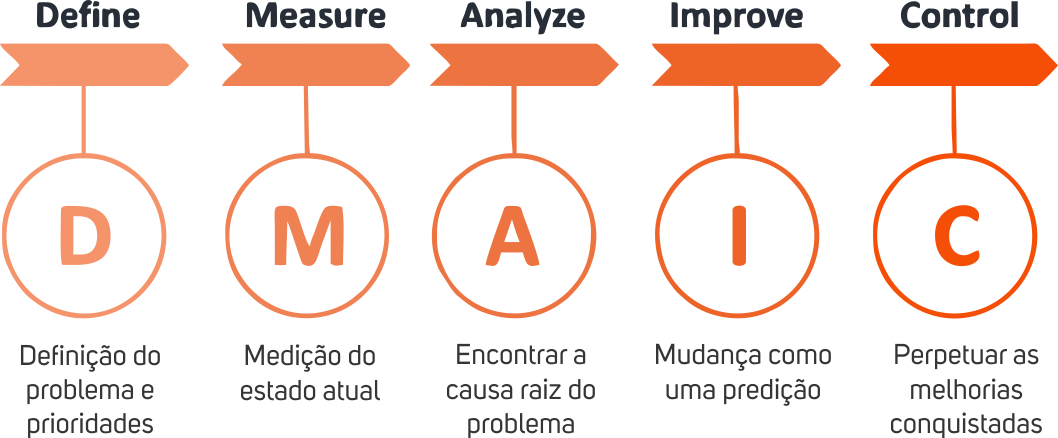

Every time a set goal is achieved, the process starts over, creating new goals and trying to achieve them. And this cycle is inspired by the DMAIC method:

Ddefine: what are the goals?

Mmeasure: what is the level of the current processes in relation to the goals?

Aanalyze: what flaws prevent current processes from achieving goals?

Increment: what improvements are needed to achieve the goals?

Wcontrol: monitoring of implemented improvements.

But now, let's go to Six Sigma, by the way, why that name?

>>Read also: Just in Time: concept, application and care

Sigma Levels

As mentioned above, the methodology is quantitative. Its name refers to the Greek letter, “Sigma”, which represents a measure of statistical variation.

The sigma will represent the frequency with which defects occur, and the search for the 99% of perfection.

In this, Sigma is divided into six levels, see:

1 Sigma: the first level represents a success rate of 30.85%, which is very low and considered unacceptable.

2 Sigma: the second level represents around 69,15% of success. It may seem like a high percentage, but if we use as an example a surgery that was successful in 69% of the cases, and in the rest resulted in complications, would you take the risk?

3 Sigma: the third level presents 93,32% of success, becoming acceptable. However, in the industry concept, if out of a million products, sixty-six thousand and eight hundred are defective, the rate of loss and waste is still very high.

4 Sigma: at this level that would be six thousand two hundred and ten failures in a million, it still represents a high error rate, even with the success rate of 99.38%.

5 Sigma: the fifth level shows 99.997% of success, showing about two hundred and thirty products with failures among a million, this being a much more comprehensive number of errors.

6 Sigma: however, at the final level, the famous Six Sigma, the success rate achieved is 99.99966%, totaling about three failures in a million, thus being considerably close to perfection.

>> Read also: Kanban: what is this method and how does it work?

How to apply the methodology?

To apply this methodology in your company, you will follow the DMAIC steps in depth.

Let's remember them:

First step: define

The first step is to have a clear understanding of the expectations for the project. Second, knowing the execution steps, those involved and the implementation steps. Also, be careful to ensure that all of this information is well aligned to prevent subsequent steps from getting lost.

Step two: measure

At this stage, the quantity and quality of available data will be combined to define indicators and find important information.

However, it is important to note that only data related to the current project should be included at this stage.

Third step: analyze

The next step is the analysis of the acquired information.

Here it will be possible to find the existing problems in the company, consider the possible causes and start thinking about strategies to solve them.

Step Four: Increment

After analyzing the information and identifying the possible causes, it is time to propose increments to improve the processes.

Thus, a new map containing the proposed innovations will be created, so that the improvements are actually implemented.

This process can take a long time, as it needs to be done calmly, be well articulated and contain real proposals in order to obtain good results.

Therefore, take it easy when implementing this methodology and do not skip steps. Develop each of the steps precisely and correctly so that the methodology achieves the expected effect.

Fifth step: control

The last stage of Six Sigma implementation is the control of processes to verify the effective application of improvements and whether they are generating the defined results.

To firmly and precisely control the processes and evaluate the results of the improvements applied, you can count on software that has real-time monitoring and that gives general visibility of the processes, such as the platform Manufacturing 360.

At this stage, it is also important to assess whether the improvements are being carried out in the best possible way, investing in employee training is a good way to ensure efficiency in this step.

Finally, when the goals set are reached and show results, restart the project. Set new goals, analyze which improvements can be imposed, in which areas the company can offer more and improve.

Get closer and closer to perfection!

By following the steps precisely, adapting the information to your company's profile and becoming more and more familiar with this methodology, you are on your way to perfection, and soon you will reach the Six Sigma level.

Guarantee even more the quality of your service, project or product, invest in a platform that automates all stages, gives you full visibility of processes, helps you reduce costs and reduce waste, making your company a more efficient and productive place .

All these features and many more can be found in Manufatura 360, the most complete platform on the market, which helps you from raw materials to decision makers!

Visit our website and talk to one of our experts to learn more.

>> Read also: Gantt chart: what is it and what is it for