Paper And Cellulose

Manufacture of pulp, paper, paperboard and cardboard and paper products.

The pulp and paper industry today

This segment has cellulose as its main component, which gives rise to the various types of paper manufactured by the sector, such as cardboard, cardboard and items such as handkerchiefs and diapers. With diverse activities and high demands, this industry makes use of various machinery and needs to produce quality products to be able to keep up, and this has become a challenge.

Stopping control of machines and the pulp and paper industry

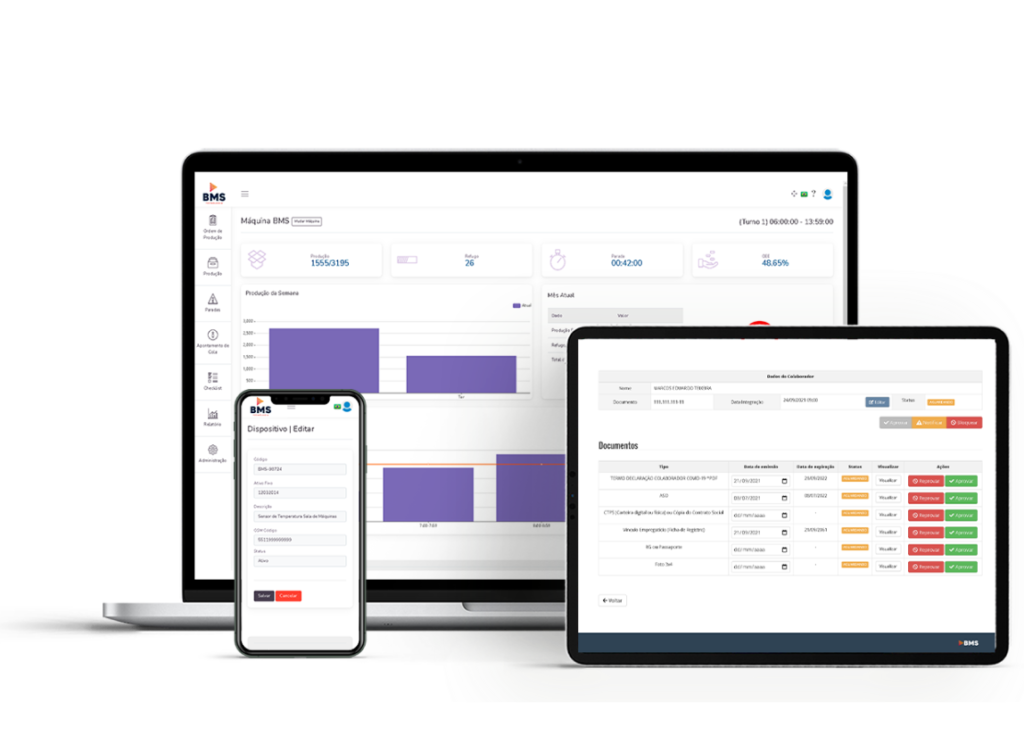

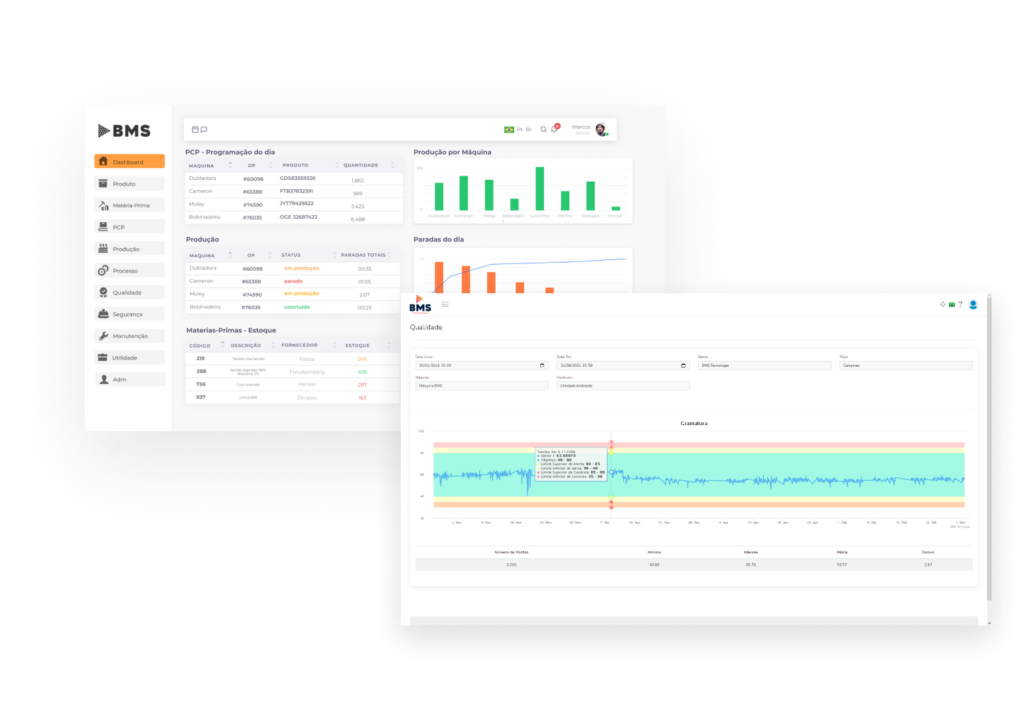

Machine stop control is fundamental for the sector. Part of the manufacture of products takes place using different types of machinery, and to do it right, the use of software that establishes connectivity and provides information about the machinery, such as Manufacture 360, is an effective solution.

Technology and maintenance

In the pulp and paper sector, predictive maintenance is effective, and with the help of technology it becomes more efficient, anticipating failures and breakdowns and reducing the amount of production losses.

Apply shutdown control technology with Manufacturing 360

Acquire the Manufacture 360 platform and have functions such as machine downtime with time and reason and variable monitoring to carry out predictive maintenance in your industry following the advice of NBR 5462. Automate all these processes, achieve efficiency and greater productivity and have scrap control to produce the best and reduce costs avoiding losses!

Define all steps in the PCP area! Establish production order, estimated production time, estimated raw material and estimated completion date. Bring your company to Industry 4.0 with the Manufacturing 360 platform and enjoy technological advances and the benefits they bring and position yourself in the competitiveness!

Check out what our customers have to say

Be part of this team too and together we will make the industry more efficient.

“We acquired a system that, due to the excellent level of service and the technical knowledge of the team, we have converted into an indispensable tool to facilitate the operation and control of our operation.”

“Excellence and high performance define the service and implementation of the BMS system at Natura. Optimizing processes and control in our operations. The company showed special attention in solving problems, enabling us to achieve the expected performance.”

“We had a very good experience with BMS, the team was very dynamic and committed to our goal, achieving the expected performance of the product.”

“I was very satisfied with both fronts: service and implementation. The company showed special attention in the contact, seeking to solve problems in the best way, in addition to an excellent package of knowledge in technology applied by the technical and technological team, which proved to be robust and modern.”

“BMS's service stood out both in service, understanding and meeting all needs, and in technical capacity, with customization and a quick response time.”