Food and drinks

Processing, storage, transport and marketing of food and beverage and manufacturing ingredients.

The food industry in Brazil

The food and beverage industry currently represents the largest sector of the Brazilian manufacturing industry. Carrying out food manufacturing activities or ingredients for food preparation, it is she who produces raw materials in the country. Being responsible for 9.7% of Brazil's GDP, regardless of crises and scenarios, this sector continued to grow and overcome challenges.

Technology and the food industry

Over time, technology-dependent strategies became necessary in this sector, such as milk pasteurization and food freezing. However, the loss of inputs is still a factor present in the food industry, but technology is already working in this area.

The challenges in this sector

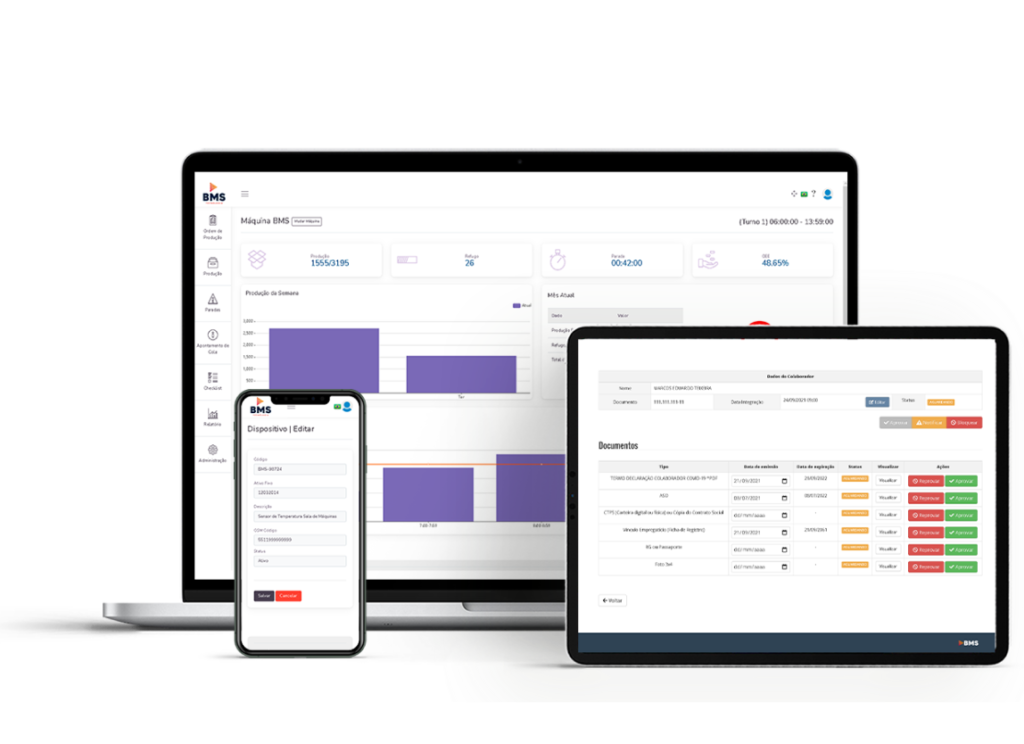

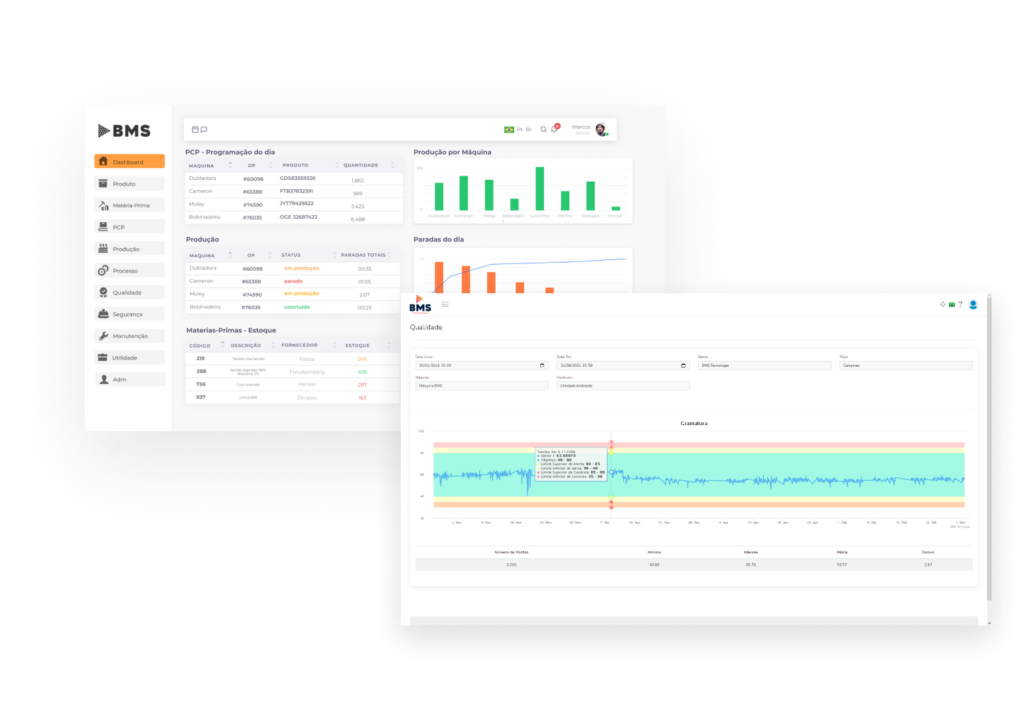

With raw material control software, such as Manufatura 360, technology is once again ready to accompany the food industry, offering solutions to the problems of loss of inputs and lack of product quality.

Overcome the challenges of the food industry with Manufacturing 360

Eliminate the waste of inputs by automating processes, which provides the guarantee and security you need. Count on the control of raw materials to find out from the supplier and date of entry to the validity and stock of the inputs, in addition to acquiring technical specifications of the products and production control to guarantee each stage of your production process!

Know the quality of your products through functions such as analysis and quality report, control of product attributes and variables and verification of parameters that you acquire with Manufatura 360. Implement industry 4.0 in your company and solve it in the most efficient and practical way the challenges your industry faces.

Check out what our customers have to say

Be part of this team too and together we will make the industry more efficient.

“We acquired a system that, due to the excellent level of service and the technical knowledge of the team, we have converted into an indispensable tool to facilitate the operation and control of our operation.”

“Excellence and high performance define the service and implementation of the BMS system at Natura. Optimizing processes and control in our operations. The company showed special attention in solving problems, enabling us to achieve the expected performance.”

“We had a very good experience with BMS, the team was very dynamic and committed to our goal, achieving the expected performance of the product.”

“I was very satisfied with both fronts: service and implementation. The company showed special attention in the contact, seeking to solve problems in the best way, in addition to an excellent package of knowledge in technology applied by the technical and technological team, which proved to be robust and modern.”

“BMS's service stood out both in service, understanding and meeting all needs, and in technical capacity, with customization and a quick response time.”